Background

At Toronto Pearson, the Airport Development and Technical Services team supports the current and future needs of the airport’s infrastructure and technical assets by providing technical care, custody, performance and planning. With the target of achieving net-zero greenhouse gas (GHG) emissions by 2050, Toronto Pearson considers all of its infrastructure and technical asset projects through a sustainability lens.

Recently, the airport undertook an initiative to enhance the resilience of Terminal 1’s heating system while staying on track for carbon emission reduction goals. Ensuring the redundancy and resiliency of power systems is a priority for the airport given its role as a key international transportation hub.

Scope of the Project

Terminal 1, Terminal 1 parking garage, and the Viscount Link train station all receive 100% of their heat from the airport’s Central Utilities Plant (CUP) through a single buried pipeline. In the event of a failure, the buildings would be without heating supply. Addressing resilience in building heating is not only important for protecting building systems and infrastructure, it is also crucial for airline passengers and staff.

The best solution to protect the heating supply to Terminal 1 was to install five redundant electric boilers rated at 1.6 MW each, which would allow for continuous operation in the event of a failure of the main heating pipeline. The Terminal 1 parking garage and the Viscount Link train station each had an external connection for rental boilers installed as part of this project for back-up heating supply in the event of a pipeline failure.

Solution Finding

During the project there was an opportunity to increase the scope from five boilers to ten for full heating redundancy. It was also redesigned for GHG reduction by offsetting load on the natural gas boilers at the CUP. The potential GHG savings was estimated at approximately 1,000 tons of carbon. The intent was to use the electric boilers each night with reduced electricity costs. The business case was amended and approved for this modification.

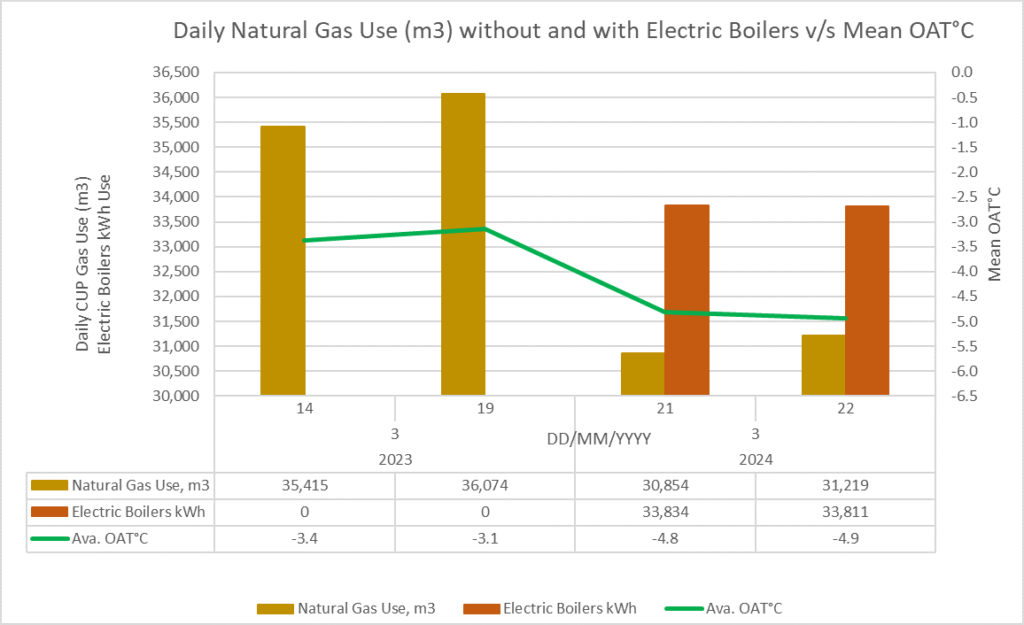

During testing it was found that the operations of certain combinations of boilers would have impacts on overall resiliency/redundancy because of capacity limits of existing electrical infrastructure. Ultimately the final solution was to run two boilers at 60% load for the heating season to offset heating demand to Terminal 1 HHF which was the farthest distance from the CUP. It was also found that the optimal temperature for running the boilers was between +5 and -5 degrees Celsius, this gave the highest gas and GHG reduction savings.

Key Metrics

The use of the two electric boilers at Terminal 1 in 2024 resulted in a net GHG reduction of ~440 tonnes CO2e at a cost of $130K (Apr YTD), based on weather normalized metered natural gas and electricity data.

Figuring out the data sources (and gaining access!) while working through operational flows and understanding capacity impacts with this small subset of boilers sets us up to be even more effective in the future when we have the ability to deploy the full fleet of 10 electric boilers for both GHG reduction and emergency reliability purposes.

“This project was the GTAA’s most significant initiative to-date to decarbonize our heating system.” – Todd Ernst, Director of Energy & Environment, GTAA

Lessons Learned

The electric boilers were installed in three areas, Area 1 and 2 having four electric boilers each and Area 3 having the remaining two boilers. Group 1 and 2 were designed and installed to work independently from the CUP heating loop and group 3 could be operation as supplementary heating to the CUP.

Ultimately the final solution was to run the two Area 3 boilers at 60% load for the heating season to offset heating demand to Terminal 1 HHF which was the farthest distance from the CUP. It was also found that the optimal temperature for running the boilers was between +5 and -5 degrees Celsius, this gave the highest gas and GHG reduction savings.

Partners in Project Green’s Energy Leaders Consortium brings together a dynamic network of energy professionals to share best practices and support collective action on energy projects. To learn more about the Energy Leaders Consortium, please contact Matt Brunette: matt.brunette@trca.ca